Having planned to construct an artificial aquifer, a small portion of the ore body was retained towards the footwall (western) side within the demineralized block with an aim to have a groundwater recharge point over the proposed backfilled area as well as to have a tapping source of water over the area subsequent to backfilling.

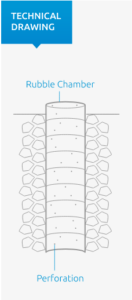

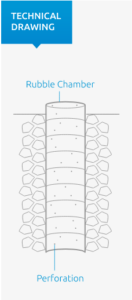

The construction of this artificial aquifer began with 2.5 m length perforated concrete pipes of 1.0mt dia. being laid over each other and connected with suitable collars to maintain the verticality and stability during the backfilling process at the predetermined location (towards footwall) over the ore body. The peripheral portion is raised by a boulder bed which forms the permeable chamber for the accumulation of the groundwater as well as monsoon water flowing into the pit. In the future, this arrangement will facilitate the tapping of groundwater. Presently nine concrete pipes of 2.5 m length have been placed up to 40.30MSL. Temporarily, a metal cap has also been installed for safety. The height of the well will be progressively increased by installing additional pipes as the reclamation proceeds till it reaches the envisaged surface level of 87 MSL

Initial Pumping Test was carried out soon after the installation of the 9th pipe during May 2012. With a pumping rate of 15M3 per hour the steady-state drawdown of 0.25m was achieved after 2 hrs of pumping. The average pumping rate is computed as 360M3 per day which can meet the later demand of one village. On resumption of mining activity which has been banned presently further pumping tests will be carried out to ascertain the quantity as well as the quality of water that would be discharged. Moreover, the project is still in an experimental stage.

Reclamation of 25 ha. of mined out area into thriving biodiversity area by adopting Principles of Ecological Restoration. Our full-fledged nursery with a capacity of 100,000 saplings is a store-house of indigenous plants as well as more than 400 species of medicinal and rare plants

All our mines are Zero Discharge sites. The overburden is backfilled in the demineralized mine pit. The rain water from the catchment area is diverted in to a mine pit and allowed to settle the sediments. Clean water is pumped out for the agriculture purpose for the benefit of nearby villagers. Service ramps at mine workshop are equipped with oil and grease trap.

VMSB has commissioned a study around its mining areas to assess the status of biodiversity as well as develop a management plan for further enhancing its status covering an area of more than 1,000 sq.m.

Having planned to construct an artificial aquifer, a small portion of the ore body was retained towards the footwall (western) side within the demineralized block with an aim to have a groundwater recharge point over the proposed backfilled area as well as to have a tapping source of water over the area subsequent to backfilling.

Having planned to construct an artificial aquifer, a small portion of the ore body was retained towards the footwall (western) side within the demineralized block with an aim to have a groundwater recharge point over the proposed backfilled area as well as to have a tapping source of water over the area subsequent to backfilling.