Ore Beneficiation

Beneficiation is the physical process of upgrading - quality of low-grade ore by removing the impurities/gangue materials that are present.

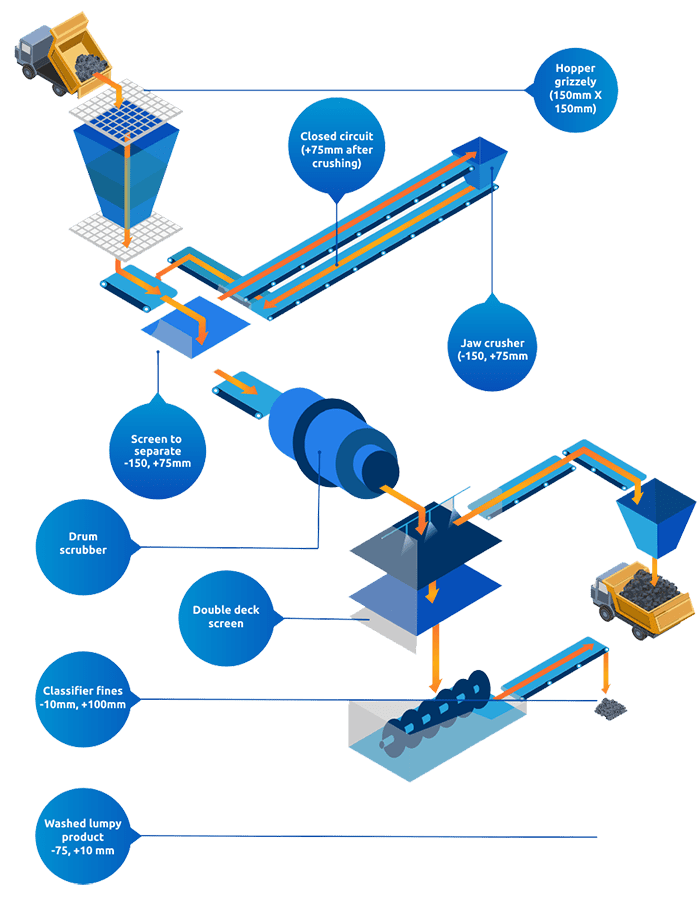

At VMSB we have a multi-line processing facility with wet beneficiation to process haematitic and siliceous ore. The capacity of the wet plant is approximately 2.5 MTPA. Wet beneficiation involves screening, crushing, scrubbing, classifying and de-sliming.

The medium/low grade Run of Mine (ROM) is fed to the plant. The feed size is maintained to 150mm. The +75mm fraction is crushed to -75mm by using crushers and the product is then mixed with the -75mm fraction.

This is then scrubbed in Rotary Drum Scrubbers and continuously discharged into the double deck linear motion wet vibrating screens, separating the product as +10, -75mm as the washed Lumpy fraction and the -10mm fraction, which then enters the Spiral Classifier.

The Classifier rake-up forms one part of the Fines product.

Overflow from the Classifier is passed through two stage Hydro Cyclones and the underflow of the secondary Cyclone is collected after passing through the De-watering Classifier.

The Primary Cyclones overflow is passed through 5 Tega Cyclones. The underflow is collected in a pond as Cyclone product and the overflow gravitates to a rake thickener to recover around 60% of process water which is re-circulated to the plant. The thickened tailing is then stored in a tailing pond. The +150mm lumps, separated at the feed hopper grizzly, are sent to the Mobile Jaw Crusher or Mobile impact Crusher for crushing.